Mashiinnada Buuxinta Vial ee Daawada

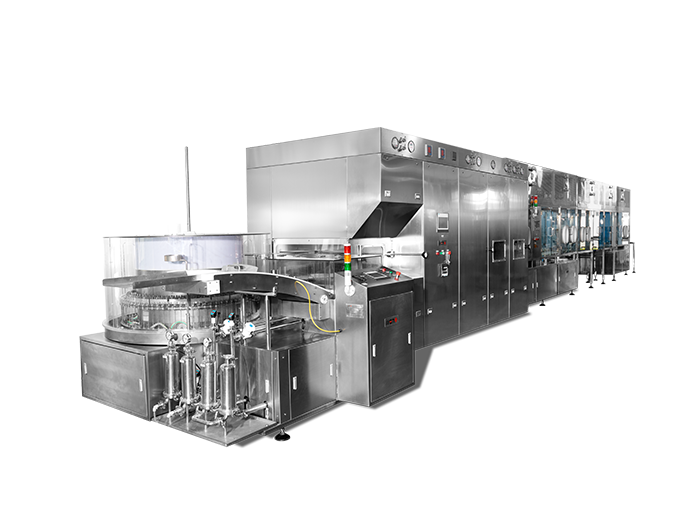

Themashiinnada buuxinta fiasalkawaxaa si aad ah loogu isticmaalaa warshadaha dawooyinka si loogu buuxiyo fijaannada maaddooyinka daawooyinka. Mashiinadan aadka u adkeysanaya waxaa loogu talagalay inay qabtaan shaqada saxda ah ee buuxinta fijaanadda degdega ah. Mashiinnada buuxinta vial waxay sidoo kale ka kooban yihiin madaxyo badan oo buuxin ah kuwaas oo ka caawinaya inay gaaraan heer buuxbuuxin sare iyo kororka wax soo saarka si ay u daboolaan baahida warshadaha dawooyinka. Waxaa jira noocyo badan oo mashiinnada buuxinta dhalooyinka ku habboon codsiyada kala duwan ee warshadaha dawooyinka.

Mabaadi'da Shaqaynta Mashiinka Buuxinta Vial

Themashiinka buuxinta fiasalkaka kooban SS slat conveyor ee dhaqdhaqaaqa dadaal la'aanta ah ee fijaannada ee mashiinka buuxinta. Laga soo bilaabo suunka qaada, fijaannada jeermis-dilaaca ah ee madhan ayaa markaa loo gudbiyaa goobta buuxinta, halkaas oo maaddooyinka dawooyinka ee loo baahan yahay lagu buuxiyo tiro sax ah. Saldhigyada wax lagu shubo waxay ka kooban yihiin madaxyo badan ama nozzles kuwaas oo awood u siinaya buuxinta fiilooyin degdeg ah iyada oo aan qashinka lahayn. Tirada madax buuxinta laga bilaabo 2 ilaa 20 ayaa loo habeyn karaa iyadoo loo eegayo shuruudaha wax soo saarka. Fijaannada waxaa si sax ah u buuxiya madaxa buuxinta, ka dib fijaanada la buuxiyey waxaa loo wareejinayaa saldhigga xiga ee khadka buuxinta. Mashiinku waxa uu ilaaliyaa madhalaysnimo joogto ah inta lagu jiro hawlaha buuxinta. Saldhigga xiga, joogsiyada ayaa la dul dhigayaa madaxa fijaannada. Tani waxay hubinaysaa in h dhallaannimada iyo daacadnimada qaybaha la ilaaliyo. Inta lagu jiro habka buuxinta, waxaa muhiim ah in la hubiyo in maaddooyinka dawooyinka iyo fijaanadaha ay ka nadiif yihiin wasakhda. Khalkhal kasta oo ku yimaada isku dhafka kiimikaad ee qaybaha waxay halis gelin kartaa dhammaan dufcaddii fijaanadaha la buuxiyey waxayna xitaa keeni kartaa diidmada dhammaan dufcaddii oo dhan. Joogsiyada waa la daboolaa oo la xiraa ka hor inta aan la aadin goobta calaamadaynta.

Noocyada Mashiinnada Buuxinta Vial

Waa caqli-gal in la fahmo noocyada kala duwan ee mashiinnada buuxinta dhalooyinka ee diyaarsan iyo naqshadooda, codsigooda iyo habka shaqada. Hoos waxaan ku sharaxaynaa noocyada kala duwan ee mashiinada buuxinta dhalooyinka oo leh macluumaadkooda:

Mashiinka Buuxinta Vial

TheMashiinka buuxinta fiishka daawadaloo isticmaalo warshadaha dawooyinka waxaa sidoo kale loo yaqaan mashiinka buuxinta fiilo la isku duro waxaana ka mid ah buuxinta fijaanada iyo caagag joojiyaha. Mashiinadan si toos ah u buuxinaya fiilooyinku waxay xaqiijiyaan joogteynta mugga, waxay yareeyaan khasaaraha alaabta, waxayna la yimaadaan nidaamka xakamaynta tayada ku dhisan ee hubinta mugga wakhtiga dhabta ah ee fijaanadaha. Mashiinnada buuxinta fiilada dawooyinka waxaa loo isticmaalaa codsiyada nadiifka ah iyo kuwa aan nadiifka ahayn labadaba.

Mashiinka buuxinta dareeraha Vial

TheMashiinka buuxinta dareeraha dhaladawuxuu ka kooban yahay mishiinka ugu muhiimsan, unscrambler, conveyor, baaquli quudinta joogsiga iyo scrambler. Suunka qaadku wuxuu u gudbiyaa fijaannada dhinaca goobta buuxinta, halkaasoo dareeraha ku jira ay ka buuxaan mashiinka. Mashiinnada buuxinta dareeraha vial waxay buuxiyaan dareeraha ama dareeraha viscosions kala duwan ee fijaannada. Mashiinadan ayaa si weyn loogu isticmaalaa warshadaha dawooyinka si loo hubiyo buuxinta saxda ah ee fijaanadaha. Mashiinka buuxinta dareeraha ee vials wuxuu ku shaqeeyaa godka quusitaanka iyo mabda'a mugga, kaas oo bixiya hawlo buuxinta nadiifka ah iyo saxnaanta.

Mashiinka Buuxinta Budada Vial

TheMashiinka buuxinta budada vialWaxay ka kooban tahay dhaqidda, nadiifinta, buuxinta, xirida iyo summeynta. Dhammaan qalabku waxay ku toosan yihiin khadka buuxinta si loo hubiyo soo-saarka joogtada ah ee fiilooyinka warshadaha dawooyinka. Mashiinka buuxinta budada fiilada tooska ah ayaa muhiim u ah warshadaha dawooyinka sababtoo ah taasi waxay ka caawisaa buuxinta granules ama budada fijaanyada.

Mashiinka buuxinta dareeraha ee la isku duro

Khadka buuxinta dareeraha ama mashiinka ayaa ku shaqeeya cadaadis sare. Sidaa darteed, waxaa sidoo kale loo kala saari karaa sida buuxinta cadaadiska dareeraha. Habkan, dareeraha la isku duro ayaa ku qulqulaya dhalada kaydinta iyadoo ku xiran culeyska marka cadaadiska ku jira kaydka dareeraha uu la mid yahay cadaadiska hawada ee dhalada.

Thekhadadka buuxinta dareeraha la isku duroWay fududahay in la shaqeeyo oo buuxi tirada saxda ah ee dareeraha dhalooyinka, weelasha ama gallons. Habka buuxinta ee lagu dhex dhisay mishiinka ayaa u oggolaanaya inay hagaajiso heerka buuxinta iyo tirada cabbirka dhalada ama weelka iyada oo aan la beddelin wax qaybo ah. Mashiinnadani waxay ku qalabaysan yihiin dareemayaal si toos ah u joojin kara habka iyada oo aan wax dhalo ah suunka.

Waqtiga boostada: Nov-20-2024